Belt Materials

Quality Studded Belts - Part 2

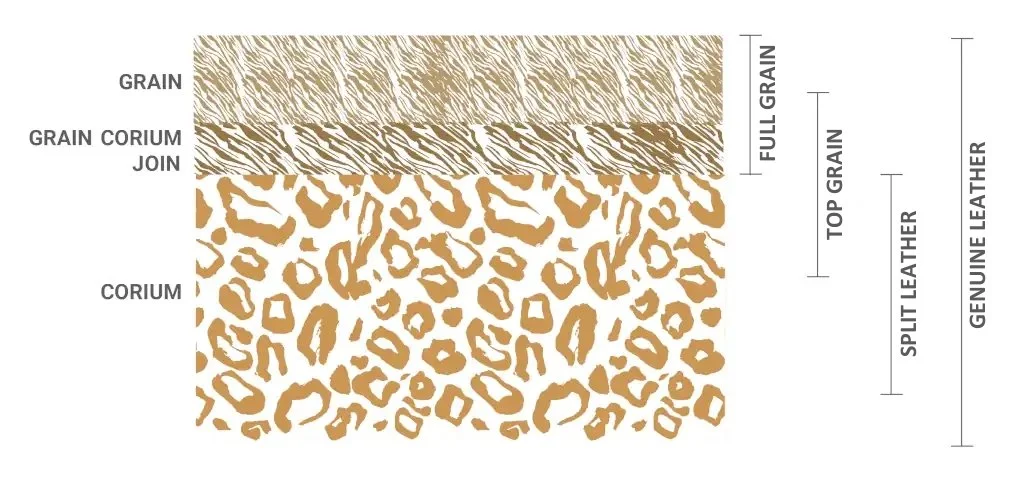

The material used in the production of a belt will dictate the quality and longevity of the product and will also dictate the price. As well as belts made of polyurethane, often called faux leather, there are a few types of real leather used in the manufacture of a studded belt but do not be fooled by the names used. All belts except full grain leather usually have a thin PU coating to give a finishing colour or texture, like snakeskin or a print. We will group the leather materials into five main categories to keep things simple, although there are varying levels of quality and different production techniques within each category. Without getting too technical these six labels are what you will most likely encounter when looking for your next studded belt.

Genuine Leather

Be careful, this marketing term can refer to any belt made from any leather of any quality but is often given to the cheapest and lowest quality of the leather produced from a hide, but technically still real “genuine” leather. The name makes it sound much better than it is, but it is actually the very bottom of the quality scale and is made from the very bottom layer of the hide. Belts made with this material will look great when new but are usually thin and will not last any longer than Bonded Leather belts. These will be the very cheapest belts available to buy, usually for around £10, but should be avoided if you want to buy a belt that will last.

Bonded Leather

Although technically a leather belt, Bonded Leather is not made of 100% leather and is not a continuous strip of leather, but is constructed using the left-over scraps from the leather industry, glued with other materials to make a flat sheet that is cut into strips. Bonded leather usually contains at least 50% leather and because it is combined with other materials these belts will be very flexible and should last a few years when used for belts. Bonded Leather belts should be considered as the entry level material for a studded belt and normally cost under £20. This material construction can be considered a positive thing as it uses scraps that might otherwise be thrown away.

Split Grain Leather

Split Leather is the most common middle quality leather that is stronger and longer lasting than Bonded Leather and is literally made from the the middle to lower layer of the hide and therefore does not have the natural grain that is found in full grain leather. The lack of grain detailing is ideal for belts that are then covered in studs or PU which would hide any natural grain or pattern in the material anyway. Split leather is a continuous strip of leather and therefore stiffer and more hard-wearing than bonded leather, but also more expensive to produce. Split Leather belts should be considered the mid-level quality belt that is longer lasting but still affordable for most customers. They will usually be a little more expensive than the entry level Bonded Leather belts costing between £20 and £30.

Top Grain Leather

Top Grain Leather is the layer just below the full grain surface but also encompases the layer used to make split grain leather products. It has a different visual look to full grain leather due to having been sanded and treated to remove any full grain blemishes. It is thinner than full grain and more supple and also thinner than split leather so is often used for jackets and other clothing but is unlikely to be used for the production of belts.

Full Grain Leather

There is a jump in price and quality between Split Grain leather and Full Grain leather which is the premium leather used on the high-end more exclusive belts. As the name suggests, Full Grain leather retains the natural pattern of the hide because it is the top layer. It is not often used for studded belts because they would hide the natural pattern. Plain belts without studs made of full grain leather will often retail at over £40 so are often too expensive for regular customers, although it produces a tougher and long lasting product. Adding studs to a belt made of full grain leather would hide much of the natural detail of the material, negating the whole reason for using full grain leather.

Faux Leather

Artificial Leather belts are most usually made from Polyurethane, also known as PU leather. This is a synthetic material that is made to look and feel like real leather by applying a polyurethane film to a fabric backing. Faux Leather belts are often cheaper to produce than leather belts and are easier to care for. PU belts vary in quality but are usually long lasting if made with quality fixings and are usually of vegan construction, the default choice for people wishing to avoid the use of animal products. Except for Full Grain leather belts which maintain the natural grain of the leather, most other belts will have a thin PU covering to give the material a nice textured finish.

Summary

In summary, when looking for your next studded belt, you should first consider the material used to construct the belt as this affects how long the belt will last. With the exception of full and top grain leather belts, all the above materials always have a PU covering to give a textured or patterned finish like a snake skin or leather grain effect. As with all things these days, it is always a trade-off between quality and price. Longevity of a belt will be very much linked to the material used, so we will discuss the lifespan of a belt in a later blog.

Next time we will discuss the belt buckle, the front and centre of your belt and the most visible and functional element of a good belt.