Anatomy of a Studded Belt

Quality Studded Belts - Part 1

Belts are a core part of our wardrobe and studded belts are a big part of our alternative lifestyle. They reflect our image of non-conformity and tell the people around what we think about boring conventional styles. But they also have a functional purpose, to keep our jeans up, to hang our keys from and for some of us to keep our waist under control ;-) In this short series of blogs we will discuss all the things you should know about how studded belts are made and what they are made from. There are lots of different types of belts out there, printed, webbing, woven, but we will talk specifically about studded belts. Let’s start with describing the different parts that make up a regular studded belt and some important points to look for.

Strap

Of course the first thing we need is the strap, wouldn’t be a belt without this! This is the long piece of material that wraps around the waist and is fastened to hold things up, hold things in, or just to hold things. Straps can be made of various materials but studded belts are mainly made from leather or PU (polyurethane), often called faux leather. Stronger and stiffer materials are needed for studded belts to hold the studs in place, where as cotton or canvas would allow the studs to move and fall out. The strap itself can come in any width but the most popular size is around 1.5 inches, between 3.5 to 4cm, to allow for 3 rows of standard pyramid studs. Another popular belt width is designed for 2 rows of studs and are around 1 inch wide, 2.5 to 3cm.

When selecting a studded belt it is important to pick the correct belt width to ensure it fits through the belt loops on your favourite pants or denims! Unless you buy an expensive belt made of full grain leather you should always examine the strap to ensure it is stitched along the edges to reduce the chance of the material splitting.

Buckle

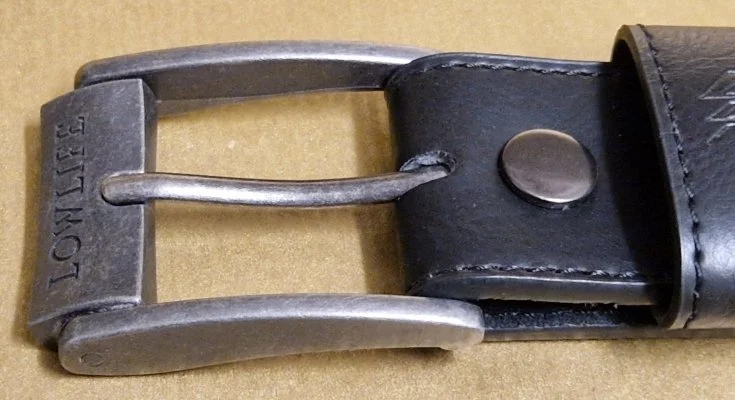

Front and centre, everybody knows the buckle is the business end of a belt and the first thing you notice when you face someone. A good buckle will keep your belt securely fastened and will also look good, adding to the studded belt style. There are many types of buckle but the most common type is the standard frame prong buckle. The design of the buckle is the quickest way to see if the manufacturer is cutting corners on the cost and quality of the studded belt. Many clothing brands use plain boring standard buckles mass produced by the belt factory. These are cheap and are easily spotted by the lack of company branding. What is the point of having a statement belt covered in your style of studs displaying your individuality, but with a boring buckle the same as everyone else?

On many belts the buckle is sewn in and not changeable, so even if you love the belt the plain buckle lets it down. If it breaks you must throw the whole belt away. If possible, try to buy a belt that has a changeable buckle attachment so you can alter the front and centre of your statement piece! There are many different types and style of buckle available and they work in different ways, so we will delve into buckles in another blog soon.

Loop

Just down from buckle there is usually a small loop of material secured to the belt through which the belt is fed to neatly hold it in place, very similar to the loops on a paid of jeans. Without this the belt would flop around loosely and get in the way. Depending on the style of buckle, the belt may not have this loop as the buckle itself may incorporate it, like a box frame buckle. Although this is a small and seemingly unimportant part of the belt, it is important that the loop is well made as it will constantly have the belt strap pushed and pulled through it so can wear out quickly and look tatty. A well made belt would nearly always have a stitched loop to prevent it from fraying.

Just down from buckle there is usually a small loop of material secured to the belt through which the belt is fed to neatly hold it in place, very similar to the loops on a paid of jeans. Without this the belt would flop around loosely and get in the way. Depending on the style of buckle, the belt may not have this loop as the buckle itself may incorporate it, like a box frame buckle. Although this is a small and seemingly unimportant part of the belt, it is important that the loop is well made as it will constantly have the belt strap pushed and pulled through it so can wear out quickly and look tatty. A well made belt would nearly always have a stitched loop to prevent it from fraying.

Studs

The studs are the main event, very visible around the waist, says everything about your individuality and, well, the main reason you buy a studded belt! There are so many different types for studs in a huge range of colours, combinations, sizes, shapes and all made with different materials. Mostly, studs on a good studded belt are made from metal and have a metalic finish, shiny or dull, chrome or pewter, brass or gunmetal. There is also a huge choice of coloured finishes usually made from metal and painted any possible colour including matt black. Occassionally coloured studs are made from acrylic which makes for a lighter and cheaper belt. The metal used to make these studs is nearly always a zinc alloy and sometimes contain nickel.

Regardless of the style of studded belt you are buying you should pay particular attention to the way the studs are attached to the strap. The old style of fixing involves pushing 2 sharp spikes through the material then folded over to hold it in place. This is usually fine but if the belt is made from particularly strong material this can force the prongs to move outwards, introducing the risk of scratching skin or damaging your clothes. If possible you should try to buy a belt from a manufacturer who has invested in stud moulds with a rivet fixing.

Eyelets

Punched holes at the end of the strap are used to secure the belt with the buckle prong or hook. The number of eyelets at the end of the belt dictate the size of the fitted belt, and whether it will be any good after a good evening out with friends! The more eyelets in a belt the more adjustable the belt will be, so at least 5 is recommended. How close together these eyelets are also dictate how precisely the belt can be adjusted.

Often, on cheaper belts, these eyelets are simply left as punch holes in the meterial with no reinforcement. This seriously affects the longevity of a belt as the hole stretches, especially if the belt is fastened tightly. Always try to buy a belt with reinforced or metal eyelets to ensure the belt lasts longer. It is a good sign of a quality belt.

Tip

Finally, the very end of the belt strap is called the tip, or end tip. This part of the belt gets a lot of abuse as it is pushed through the buckle, through the loop and also through the belt loops of your trousers. It is often plain and just tucked away and forgotten, but is actually a very visible part of the belt and is as important as the studs themselves. This tip is very prone to splitting as it ages so you should always buy a belt that has been stitched to prevent this, or a belt that has a metal end tip attached. As the tip of the belt will be visible and overlap some studs when fastened consider a belt with added decoration to continue the styling.

Summary

Now that you know the parts that make up a belt, look out for our blogs that delve deeper into what you need to know. There are so many factors that will determine if you are buying a quality belt that will last, or a belt that will give you style for a short time but will soon look tattered and fall apart. Look at each element of the belt and study the finer details to see if the brand has cut corners to maximise their profit, or invested in making a quality belt that they will put their name to.

Next time we will discuss the material used to make a studded belt, the quality of the different types of leather and the faux leather alternative.